Partners hold REVO Master Class Open House at Bobst, Italy

The partners in the REVO Technology Team – Americk Packaging, Apex International, AVT, BOBST, DuPont, Esko, Flint Group, UPM, X-Rite PANTONE – are holding a Master Class Open House event from today (November 29) until Thursday (December 1) in the Competence Center of Bobst Firenze, Italy, which is also the seat of the REVO Academy.

The event is focused on sharing with packaging and label manufacturers the latest technologies developed by the REVO partners, which concur to making available to the industry an integrated full circle digital flexo solution.

The REVO Master Class Open House at Bobst Firenze will offer a comprehensive half day program of classes – held in the morning and repeated in the afternoon – where visitors will have the opportunity of learning and discussing the applications and benefits of the REVO process and seeing from live demonstrations how it succeeds in providing exceptional efficiency and flexibility to printing of any run lengths – from very short runs upwards, using multi-process converting for high performance value-added label, flexible or carton packaging production.

The REVO Master Class Open House topics to be presented and discussed include:

- The reality of a converter’s three year experience with implementation of the REVO technology;

- REVO profitability vs conventional printing;

- REVO reality – steps and common errors;

- The use and safety of seven-colour UV ink printing in the food industry

Converters attending the Master Class Open House will also see how the REVO Academy can provide in-depth training and technical support in the implementation of the REVO technologies.

The REVO partners have been working together since 2014, when they decided to pool their know-how and experience to drive the advancement of flexography towards a digitalised manufacturing workflow, from pre-press to output reels, validated by global digital quality standards.

The REVO technologies and know-how pooled by the partners are:

- Field test and validation of the REVO process – Americk Packaging

- GTT Anilox rollers suitable for REVO specifications – Apex International

- Press control and quality control – AVT

- Flexo plates suitable for REVO specifications – DuPont

- Seven colours separation software and control hardware suitable for REVO specifications – ESKO

- Flexo inks suitable for REVO specifications – Flint Group

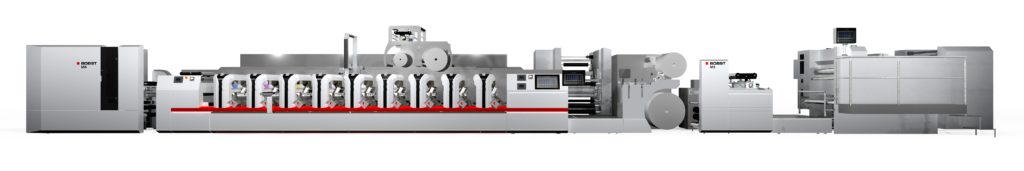

- Printing and converting equipment, digital automation for REVO specifications – BOBST

- Substrates for REVO specifications – UPM

- Colour measuring and standard system – X-Rite PANTONE