TRESU Group provides the key to leaner flexo production

Flexo technology provider, TRESU Group, has announced a new holistic care programme that enables customers worldwide to gain maximum value from complete workflows that feature TRESU ancillary equipment, printing units and processes.

Under the supervision of experienced TRESU technical staff, Global Service Concept comprises round-the-clock support, on-going machine optimisation, training and testing, thereby providing a framework for driving waste out of the customer’s processes.

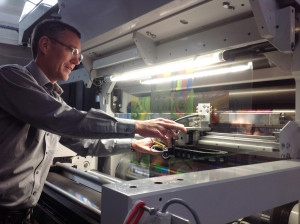

Besides rapid-response 24-hour remote diagnostics, on-site services are integral to the programme. These include management of installations, maintenance and repairs, and consultation to help customers implement lean and cleaner manufacturing practices in areas such as setup time reduction, ink and substrate performance and human-machine interaction. Furthermore, TRESU’s Test and Demo Centre at its global headquarters provides a location for training programmes that give operators and staff in-depth understanding of the equipment and hands-on experience with machine components.

Peder Larsen, global service manager, TRESU Group, commented: “In an age when service flexibility is the key to providing competitive edge, printers depend on solutions that deliver lowest total ownership cost, repeatable quality and optimisation of productivity. And with end-users demanding tighter colour tolerances and shorter production runs, problem-solving and maintenance can only be effective when taking the whole process into consideration.

“TRESU’s Global Service Concept, backed by a team of skilled technicians with up to 20 years’ industry experience, gives printers the reassurance of smoothly integrated systems that work to full potential throughout the product life, full control the process, and waste minimisation at every stage.”

Highlights of TRESU Group’s ancillary product programme are the F10 iCon ink supply system that automates ink pressure and viscosity in flexo printing machines, and sealed, pressure-controlled chambered doctor blade systems enable direct, foam-free transfer of ink or coating medium to the anilox roll and fast changeover times. Also in the TRESU product line-up are bespoke flexo printing units for a range of packaging and industrial markets, and complete printing and converting lines for folding carton and flexible packaging applications.